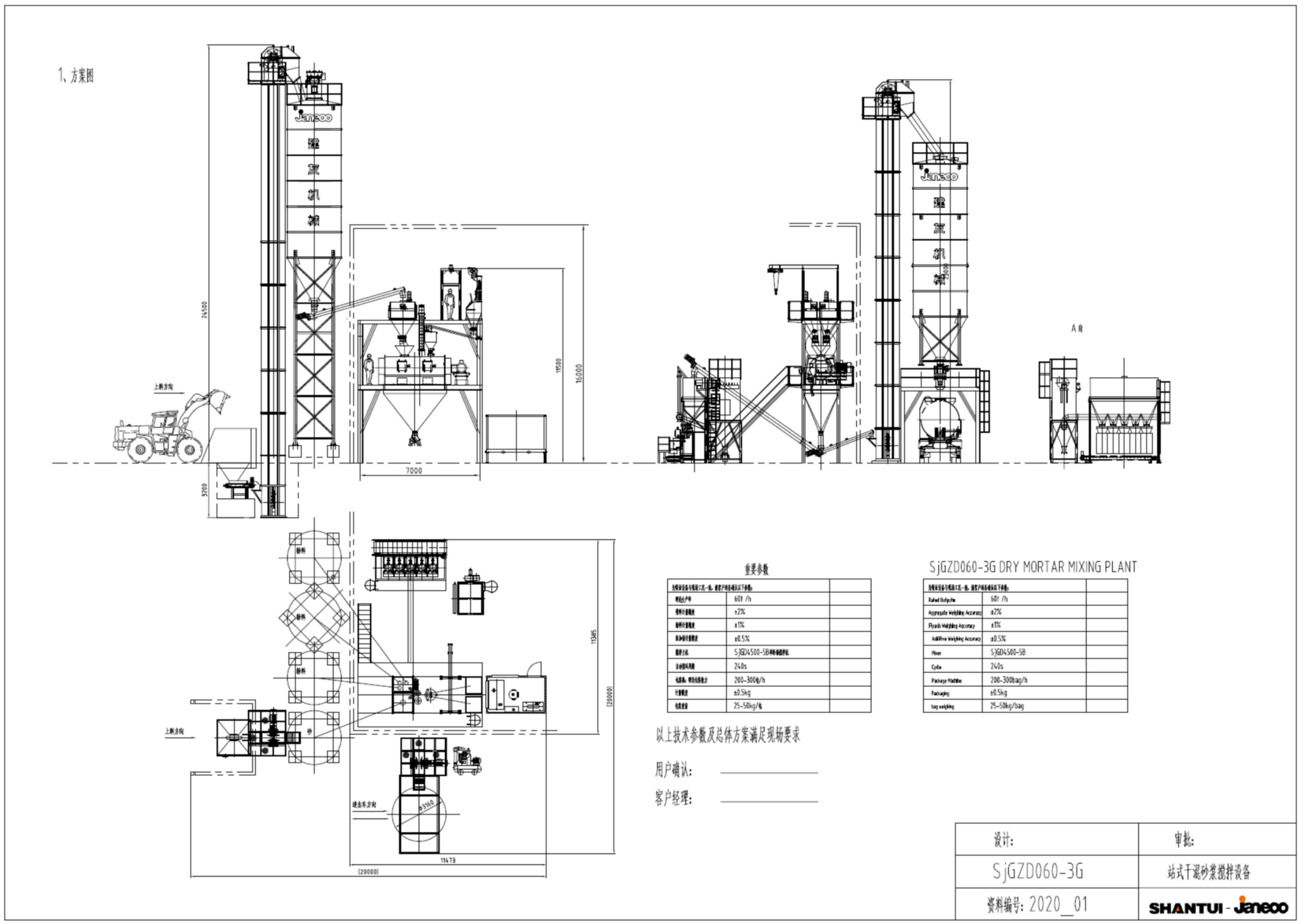

SjGZD060-3G Station Type Garing Motar batching plant

Spesifikasi utama

1. spesifikasi utama

Produktivitas teoritis 60t/jam

Mixer SjGD4500-5B

akurasi pangukuran agregat 2

Akurasi pengukuran semen 1%

akurasi pangukuran aditif 0,5%

Sand silo volume 72m3

Volume silo semen 72m3

Volume silo aditif 0,5m3

Kapasitas packing 200-300 bags/h/set

Total daya 140kW (ora kalebu silo lan screw conveyor)

1. Pasir silo

| Volume | 72m3 |

| Dhiameter | 3,2m |

2. Silo semen

| Volume | 72m3 |

| Dhiameter | 3,2m |

3. Silo aditif

| Volume | 0,5m3 |

4. Sand batching screw conveyor

| diameteripun meneng | 323 mm |

| kapasitas | 35m3/h |

5. Sand batching screw conveyor

| diameteripun meneng | 273 mm |

| kapasitas | 50m3/h |

6. hopper ukur agregat

| jinis | timbangan elektronik |

| Nilai maksimal | 3000Kg |

| Akurasi | ± 2% |

7. Hopper ukur semen

| jinis | timbangan elektronik |

| Nilai maksimal | 2500Kg |

| Akurasi | ± 1% |

8. Hopper ukur aditif

| jinis | timbangan elektronik |

| Nilai maksimal | 150Kg |

| Akurasi | ± 0,5% |

9. Pengaduk

| Pengaduk | SjGD4500-5B |

| daya motor | 90kw |

| Daya blade | 4x5.5kw |

10. Mesin Packing

| Kapasitas packing | 200-300 tas / jam / set |

| Saben tas bobot | 25-50 Kg |

| Akurasi | ± 0,5 Kg |

11. sistem pneumatik

| daya kompresor hawa | 30 kW |

| tekanan | 0,75 MPa |

12.sistem mbusak bledug

| Nyaring | 60m2 |

| daya | 7,5 kW |

20. sistem kelistrikan

Sistem iki didhukung dening ac 380V lan 50Hz telung fase papat (lima) sistem kabel.

21. Kontrol komputer

Manual lan otomatis

22. wektu siklus

| Auto | 240s |

Katrangan

SjGZD060-3G stasiun jinis garing mortir nyawiji peralatan jenis peralatan dirancang lan dikembangaké dening kita perusahaan miturut produk padha ing luar negeri lan digabungake karo kahanan nyata ing China.Iku cocok kanggo nyawiji mortir garing biasa lan mortir garing khusus.

Peralatan utama adopts struktur stasiun, kalebu 1 sand bin (72m3 / Piece), 3 bubuk bin (72m3 / Piece), lan 2 aditif bin (0.5m3 / Piece).Wedhi diangkat dening mesin ember, wêdakakêna diangkut. menyang silo wêdakakêna dening truk tank akeh, lan loro aditif diangkat menyang lapisan silo aditif dening piranti ngangkat listrik lan sijine menyang silo aditif manually.Sand, wêdakakêna, aditif nggunakake meneng conveyor batching, ngukur ember nggunakake ukuran ukuran elektronik. , Akurasi pangukuran dhuwur, kesalahan cilik.Sistem kontrol nganggo kontrol manual lan otomatis.Sistem kasebut nduweni fungsi ngunci mandiri lan inter-locking sing sampurna kanggo njamin operasi sistem sing akurat lan dipercaya, lan nduweni fungsi deteksi kesalahan lan weker sing umum.

Konfigurasi

| 一, gedung utama | ||||

| Ora. | Katrangan | Item | Qty | Tetembungane |

| 1 | timbangan | 1 |

| |

| timbangan maks.3000kg | 1 | |||

| tekanan load cell | 3 | |||

| load cell nyambungake bagean | 3 | |||

| (DN300) katup kupu-kupu pneumatik (DN300) | 2 | |||

| MVE60/3 vibrator MVE60/3 | 1 | |||

| timbangan semen Max.2500kg | 1 | |||

| tekanan load cell | 3 | |||

| load cell nyambungake bagean | 3 | |||

| katup kupu pneumatik (DN250) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 2 | silo panyimpenan aditif | 1 |

| |

| tong sampah tambahan (volume: 0,5m3) | 2 | |||

| Indikator resistensi twist-action | 2 | |||

| katup kupu manual (DN250) | 2 | |||

| transverter | 1 | |||

| vibrator MVE60/3 | 2 | |||

| 3 | timbangan aditif | 1 |

| |

| Maks.timbangan 150kg | 1 | |||

| mbukak sel | 3 | |||

| katup kupu pneumatik (DN200) | 1 | |||

| katup kupu pneumatik Ø250 | 1 | |||

| MVE60/3 vibrator MVE60/3 | 1 | |||

| 4 | piranti angkat aditif | 1 |

| |

| pigura | 1 | |||

| 1000Kg Electric Hoist 1000KG | 1 | |||

| 5 | Piranti pakan manual | 1 |

| |

| tong sampah manual | 1 | |||

| katup kupu pneumatik (DN200) | 1 | |||

| 6 | sistem campuran |

|

| |

| dasar pendukung (struktur baja Q235) | 1 | |||

| Badan tangki (Struktur Baja 16Mn) | 1 | |||

| gerbang akses (Struktur Baja 16Mn) | 2 | |||

| ischarging gate (struktur baja 16Mn) | 1 | |||

| 90KW piranti nyawiji | 1 | |||

| nyampur poros lan poros mburi | 1 | |||

| piranti discharging | 1 | |||

| Piranti sampling | 1 | |||

| sampling tube body (komponen struktur) | 1 | |||

| silinder sampling | 1 | |||

| katup arah manual | 1 | |||

| piranti campuran tambahan | 4 | |||

| piranti fly cutter | 4 | |||

| 7 | hopper rampung | 1 |

| |

| awak hopper (16Mn) | 1 | |||

| Indikator resistensi twist-action | 1 | |||

| vibrator MVE60/3 | 1 | |||

| katup kupu manual (DN250) | 2 | |||

| 8 | Kemasan produk | 1 |

| |

| rampung hoppe | 1 | |||

| Pigura | 1 | |||

| Indikator resistensi twist-action | 2 | |||

| vibrator MVE60/3 | 1 | |||

| Mesin kemasan saku katup | 1 | |||

| Sabuk (L=4500m,B=650mm,2.2kw) | 1 | |||

| 9 | piranti mbusak bledug | 1 |

| |

| 7.5KWPulse jotosan Filter | 1 | |||

| Pipa mbusak bledug | 1 | |||

| 10 |

| 1 |

| |

| 30KW kompresor udara 30KW | 1 | |||

| AFF22C-10D | 1 | |||

| 1m3 | 1 | |||

| Gas-way joint | 1 | |||

| 11 | sistem kontrol | 1 |

| |

| komputer | 1 | |||

| komponen listrik | 1 | |||

| Monitor LCD | 1 | |||

| 打印机 printer | 1 | |||

| UPS | 1 | |||

| konsol kontrol | 1 | |||

| kabinèt | 1 | |||

| kabel, kabel lan jembatan. | 1 | |||

| 12 | kamar kontrol | 1 |

| |

| Kerangka ruang kontrol | 1 | |||

| Dekorasi kamar kontrol | 1 | |||

| Cahya lan ngalih | 1 | |||

| AC 1P Kab | 1 | |||

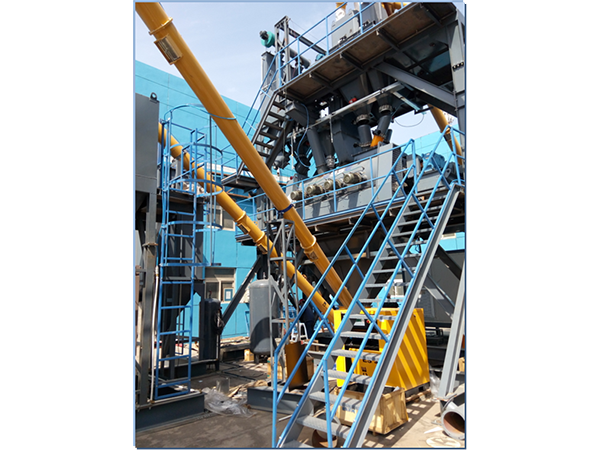

| 13 | struktur baja | 1 |

| |

| platform | 1 | |||

| andha | 1 | |||

| sikil landing | 1 | |||

| screw conveyer | ||||

| 14 | φ323X5500mm 18.5KW screw conveyer | 1 |

| |

| 15 | φ323X3000mm 15KW screw conveyer | 1 |

| |

| 16 | φ219X5000mm 7.5KW screw conveyer | 1 |

| |

| 17 | φ219X7000mm 7.5KW screw conveyer | 1 |

| |

| 18 | φ219X9000mm 9.2KW meneng conveyer | 1 |

| |

| 19 | Ø 114x1500mm, screw conveyer | 2 |

| |

| 20 | Ø323-9000 screw conveyer | 1 |

| |

| 21 | SNC100 silo | Dhiameter: 3.2m, V: 72m3 | 3 |

|

| Piranti break arch | 3 |

| ||

| Katup manual (DN300) | 3 |

| ||

| Rotary level meter | 6 |

| ||

| Silo tutup aman ndhuwur | 3 |

| ||

| Silo ndhuwur pulsa bali flush Filter | 3 |

| ||

| 22 | SNC100 silo | Dhiameter: 3.2m, V: 72m3 | 1 |

|

| Katup manual (DN300) | 1 |

| ||

| Rotary lever meter | 2 |

| ||

| Silo ndhuwur pulsa bali flush Filter | 1 |

| ||

| 23 | SNC100 silo | Dhiameter: 3.2m, V: 72m3 | 1 |

|

| Piranti break arch | 1 |

| ||

| Katup manual (DN300) | 1 |

| ||

| Rotary level meter | 2 |

| ||

| Silo ndhuwur pulsa bali flush Filter | 1 |

| ||

| sikil dhukungan, awak silo lan aksesoris | 1 |

| ||

| 24 | Ember Lift 60m3 / h | 2 |

| |

| Lift (24m, 11kw) | ||||

| Ladders lan Maintenance Platform | ||||

| feeding lan discharging chute | ||||

| 25 | katup pneumatik | 1 |

| |

| dhasar ndhukung | 1 | |||

| silinder | 1 | |||

| katup elektromagnetik | 1 | |||

| 26 | Pemuat mortir massal | Pemuat mortir massal | 1 |

|

| 27 | hopper | 1 |

| |

| buchet | 1 | |||

| (B=650mm,2.2kW) Sabuk | 1 | |||