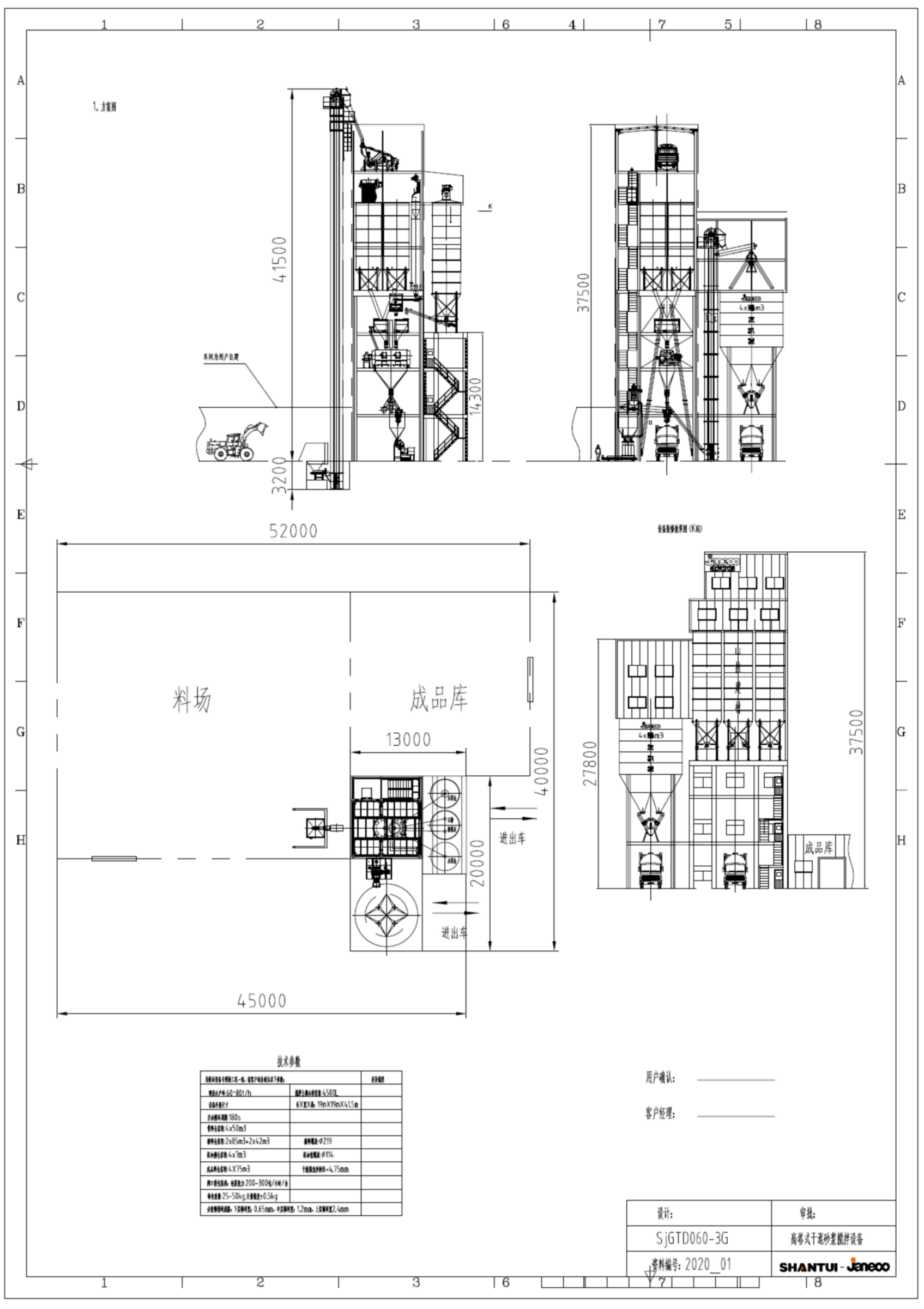

SjGTD060-3G Tower Type Dry Mortar Batching Plant

Spesifikasi utama

1. spesifikasi utama

Produktivitas teoritis 60-80t / jam

Mixer SjGD4500-5B

akurasi pangukuran agregat ± 2%

Akurasi pengukuran semen ± 1%

akurasi pangukuran aditif ± 0,5%

Pasir silo volume 4X50m3

Volume silo semen 2X85m3+2X42m3

Volume silo semen 2X85m3+2X42m3

Kapasitas packing 200-300 bags/h/set

Kapasitas packing 200-300 bags/h/set

1. Lift pengangkat pasir

| Jinis | TB60 |

| Kacepetan hoist | 1.1m/s |

| Kapasitas teoretis | 60m3/h |

| daya motor | 18,5 kW |

2. Pipa pasir batching chute

| diameteripun chute | 323 mm |

3. Semen batching screw conveyor

| diameteripun meneng | 219 mm |

| kapasitas | 60t/jam |

| daya motor | 7,5KW |

4. Fly awu batching meneng conveyor

| diameteripun meneng | 219 mm |

| kapasitas | 60t/jam |

| daya motor | 7,5 kW |

5. Thickening bubuk batching screw conveyor

| diameteripun meneng | 219 mm |

| kapasitas | 60t/jam |

| daya motor | 7,5 kW |

6. agregat ukur hopper

| jinis | timbangan elektronik |

| Nilai maksimal | 4000kg |

| akurasi | ± 2% |

7. hopper ukur semen

| jinis | timbangan elektronik |

| Nilai maksimal | 2000kg |

| akurasi | ± 1% |

8. hopper ukuran aditif

| jinis | timbangan elektronik |

| Nilai maksimal | 150 kg |

| akurasi | ± 0,5% |

9. sistem mixer

| Pengaduk | SjGD4500-5B |

| daya motor | 90KW |

| daya lading | 4x5.5kw |

10. pakan impeller

| diameteripun | 400 mm |

| daya motor | 3KW |

| kapasitas | 50m3/h |

11. mesin packing

| kapasitas packing | 200 ~ 300 tas / jam / set |

| saben bobot | 25-50 Kg |

12. mesin sabuk

| mesin sabuk | 2KW |

13. produksi meneng conveyor

| jinis | GX500 |

| kapasitas | 70m3/jam |

| daya motor | daya motor |

14 mesin akeh

15. produksi hoist elevator16.2 produksi screw conveyor 217. sistem kelistrikan19. sistem kelistrikan

Sistem iki didhukung dening ac 380V lan 50Hz telung fase papat (lima) sistem kabel.

20. kontrol komputer

kontrol komputer

21. wektu siklus

otomatis: 180s

| kapasitas | 100t/jam |

| jarak fleksibel saka discharging gate | 1200 mm |

| daya motor | 0,55 kW |

| daya penggemar Filter | 2,2 kW |

| jinis | TB110 |

| kacepetan hoist | 1.1m/s |

| kapasitas | 110m3 / jam |

| daya motor | 22 kW |

| diameteripun meneng | GX500 |

| kapasitas | 70m3/jam |

| daya motor | 7,5KW |

| daya kompresor hawa | 37 kW |

| tekanan | 7,5KW |

Katrangan

Sjgtd060-3g peralatan batching mortir garing nganggo struktur menara, kanthi produktivitas gedhe, hemat energi lan perlindungan lingkungan, karakteristik stabil lan dipercaya, utamane digunakake kanggo nyampur mortir garing biasa.

Peralatan utama nganggo struktur menara, kanthi 4 silo pasir, 4 silo bubuk, 4 silo aditif lan 4 silo produk rampung.Wedhi kanggo nggunakake kabel biasa diangkat dening mesin ember lan disimpen ing wedhi bin sawise biji screening.Powder dikirim menyang wêdakakêna bin dening akeh tanker.The aditif diangkat menyang storehouse aditif dening piranti ngangkat listrik lan sijine menyang storehouse aditif kanthi manual .

Pasir adopts ngusapake pipe batching, bahan bubuk, aditif nganggo spiral conveyor batching.

Ember pangukuran nganggo skala elektronik kanggo ngukur, sing nduweni akurasi pangukuran sing dhuwur lan kesalahan cilik.

Sistem kontrol adopts manual lan otomatis control.The sistem wis sampurna poto-ngunci lan inter-locking fungsi kanggo mesthekake operasi akurat lan dipercaya saka sistem, lan wis deteksi fault umum lan fungsi weker.

Konfigurasi

| peralatan standar | ||||

| Ora. | Katrangan | Item | Qty | Tetembungane |

| 1 | piranti kerekan pasir garing | 1 |

| |

| lift (42m) | 1 | |||

| andha lan platform | 1 | |||

| chute saka dipakani lan discharging | 1 | |||

| 2 | piranti layar gradasi | 1 |

| |

| 3 lapisan layar geter (2x3.6KW) ngisor: 0.65mm, tengah: 1.2mm, ndhuwur 2.4mm | 1 | |||

| pipa bledug | 1 | |||

| 3 | saringan pasir silo | 1 |

| |

| pipa chute φ325 | 4 | |||

| katup pneumatik (DN300) | 4 | |||

| masang katup | 4 | |||

| pulsa bali flush filter HMC48 | 1 | |||

| 4 | skala pasir | 1 |

| |

| regane maksimal 4000kg | 1 | |||

| sensor tekanan | 3 | |||

| sendi sensor | 3 | |||

| katup pneumatik (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | skala semen | 1 |

| |

| regane maksimal 2000kg | 1 | |||

| sensor tekanan | 3 | |||

| sendi sensor | 3 | |||

| katup pneumatik (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 6 | skala aditif | 1 |

| |

| regane maksimal 150kg | 1 | |||

| sensor tekanan | 3 | |||

| katup pneumatik (DN200) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 7 | piranti dipakani manual | 1 |

| |

| hopper dipakani lan tutup | 1 | |||

| katup pneumatik (DN200) | 1 | |||

| 8 | saringan aditif | 1 |

| |

| katup pneumatik (DN150) | 4 | |||

| saringan silo aditif | 1 | |||

| 9 | sistem pencampuran (V: 4500L) | 1 |

| |

| piranti nyopir 90KW | 1 | |||

| piranti nyampur | 1 | |||

| kacepetan dhuwur Rotary scraper 5.5KW | 4 | |||

| gapura ngeculake | 1 | |||

| tank campuran | 1 | |||

| piranti sampel | 1 | |||

| 10 | Hopper utama lan akeh | 1 |

| |

| awak hopper | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| feeder impelled | 1 | |||

| pneumatik 4 fase | 1 | |||

| rotary level meter ILTC0 | 1 | |||

| mesin akeh | 1 | |||

| 11 | mesin packing produksi |

|

| |

| awak hopper | 1 | |||

| rotary level meter ILTC0 | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| 2 metu mesin packing | 1 | |||

| mesin sabuk produksi (B = 650mm, 2.2kw) | 1 | |||

| 12 | hoist produksi lan distributor | 1 |

| |

| lift (24m, 15kw) | 1 | |||

| andha lan platform | 1 | |||

| chute saka dipakani lan discharging | 1 | |||

| dhukungan meneng | 1 | |||

| rotary distrubuter 0.75KW | 1 | |||

| 13 | produksi massal | 1 |

| |

| katup insert pneumatik | 4 | |||

| katup pneumatik (DN300) | 4 | |||

| hopper tanisi | 1 | |||

| mesin akeh | 1 | |||

| 14 | packing piranti Filter | 1 |

| |

| pulsa bali flush filter (1.5kw) | 1 | |||

| pipa saringan | 1 | |||

| katup manual (DN150) | 1 | |||

| 15 | sistem pneumatik | 1 |

| |

| kompresor hawa | 1 | |||

| tank panyimpenan 1m3 | 1 | |||

| Tangki panyimpenan 0,3m3 | 2 | |||

| saringan utama | 1 | |||

| pengering | 1 | |||

| sendi | 1 | |||

| 16 | sistem kontrol | 1 |

| |

| komputer industri | 2 | |||

| piranti lunak | 2 | |||

| komponen listrik | 1 | |||

| Monitor LED 19 Kab | 2 | |||

| printer | 1 | |||

| sumber daya | 1 | |||

| meja operasi | 1 | |||

| kabinet listrik | 1 | |||

| kabel lan kabel | 1 | |||

| 17 | sistem pengawasan | 1 |

| |

| kamera warna | 4 | |||

| lensa cemera | 4 | |||

| monitor LED | 1 | |||

| masang DV | 1 | |||

| 18 | Struktur baja utama |

|

| |

| sasis | 1 | |||

| andha | 1 | |||

| nyokong | 1 | |||

| pangiriman panyimpenan lan dekorasi njaba | ||||

| 19 | semen screw conveyor | φ219X6000 mm | 2 |

|

| 20 | semen screw conveyor | φ219X5000mm | 2 |

|

| 21 | 机additive screw conveyor | φ114x3000 mm | 2 |

|

| 22 | aditif meneng conveyor | φ114x2000mm | 2 |

|

| 23 | produksi screw conveyor | GX500-4500 | 1 |

|

| 24 | produksi screw conveyor | GX500-2500 | 1 |

|

| 25 | Silo panyimpenan pasir | 4 |

| |

| V: 50m3 | 4 | |||

| katup manual | 4 | |||

| rotary level meter | 8 | |||

| 26 | silo panyimpenan semen | 2 |

| |

| v:85m3 | 2 | |||

| pemecah lengkung | 2 | |||

| katup manual (DN300) | 2 | |||

| rotary level meter | 4 | |||

| katup aman | 2 | |||

| silo ndhuwur pulsa bali flush Filter | 2 | |||

| 27 | silo panyimpenan semen | 1 |

| |

| V: 2x42m3, isolasi silo | 1 | |||

| pemecah lengkung | 2 | |||

| katup manual (DN300) | 2 | |||

| rotary level meter | 4 | |||

| katup aman | 2 | |||

| silo ndhuwur pulsa bali flush Filter | 2 | |||

| 28 | silo panyimpenan produksi | 1 |

| |

| V: 4x75m3, isolasi silo | 1 | |||

| pulsa bali flush filter (1.5kw) | 1 | |||

| pemecah lengkung | 4 | |||

| katup manual | 4 | |||

| rotary level meter | 8 | |||

| 29 | silo aditif | 4 |

| |

| v:7m3 | 4 | |||

| rotary level meter | 4 | |||

| vibrator MVE 60/3 | 4 | |||

| katup manual (DN300) | 4 | |||

| 30 | piranti kerekan listrik | 1 |

| |

| kerekan listrik | 1 | |||

| rel, kandhang | 1 | |||

| 31 | dekorasi | dekorasi 1500m2(0.5mm) | 1 |

|

| pigura awak | 1 | |||