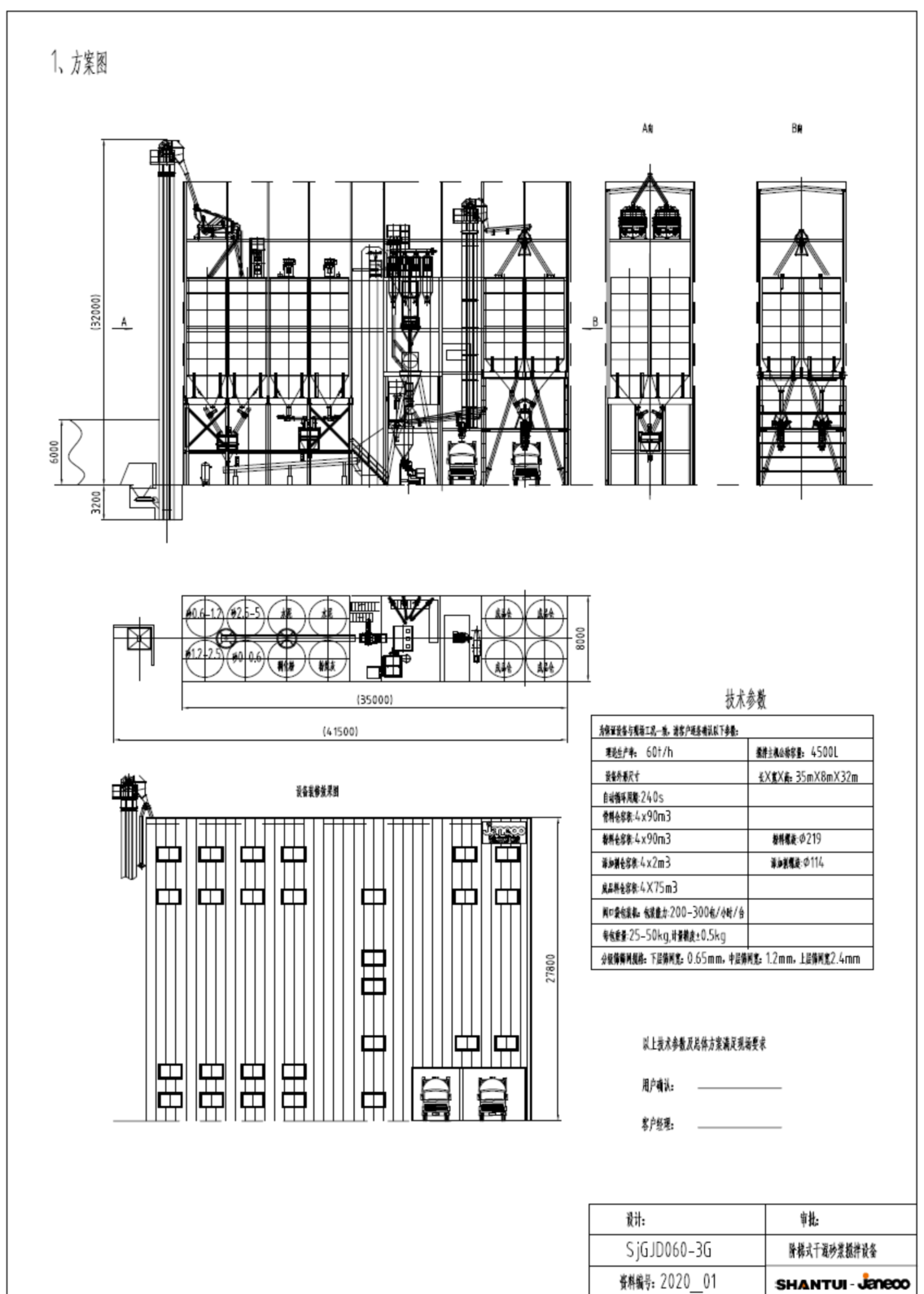

SjGJD060-3GStepped Type Dry Mortar batching plant

Spesifikasi utama

1. spesifikasi utama

Produktivitas teoritis 60t/jam

Mixer SjGD4500-5B

akurasi pangukuran agregat ± 2%

Akurasi pengukuran semen ± 1%

akurasi pangukuran aditif ± 0,5%

Sand silo volume 4X90m3

Silo semen volume 4X90m3

Volume silo aditif 4X2m3

Kapasitas packing 200-300 bags/h/set

Total daya 330 kW

1. Lift pengangkat pasir

| Jinis | TB60 |

| Kacepetan hoist | 1.1m/s |

| Kapasitas teoretis | 60m3/h |

| daya motor | 15 kW |

2. Layar dinilai

| daya motor | 2x3.6kW |

| lapisan gradasi | 3 lapisan |

3. Pasir Silo

| Volume | 90m3 |

| Dhiameter | 3,4m |

4. Silo semen

| Volume | 90m3 |

| Dhiameter | 3,4m |

5. Silo aditif

| Volume | 2m3 |

| Ukuran | 0,9x0,9m |

6. Silo Produksi

| Volume | 75m3 |

| Dhiameter | 3,4m |

7. Semen batching screw conveyor

| Dhiameter | 219 mm |

| Kapasitas | 60t/jam |

| daya motor | 5,5 kW |

8. Agregat ukur hopper

| jinis | timbangan elektronik |

| Nilai maksimal | 4000kg |

| Akurasi | ± 2% |

9. hopper ukur semen

| Pengaduk | SjGD4500-5B |

| Nilai maksimal | 1500kg |

| Akurasi | ± 1% |

10. hopper ukuran aditif

| jinis | timbangan elektronik |

| Nilai maksimal | 150 kg |

| Akurasi | ± 0,5% |

11. lif campuran

| jinis | TB110 |

| tekanan | 1.1m/s |

| kapasitas | 110m3/h |

| daya motor | 22 kW |

12. Sistem mixer

| Pengaduk | SjGD4500-5B |

| daya motor | 90kw |

| daya lading | 4x5.5kw |

13. mesin packing

| kapasitas packing | 200 ~ 300 tas / jam / set |

| saben bobot | 25-50 Kg |

| akurasi | ±0,5 Kg |

14. produksi meneng conveyor 1 sadurunge elevator

| jinis | GX400 |

| kapasitas | 42m3/h |

| daya motor | 15 kW |

15. produksi meneng conveyor 2 ing akeh

| jinis | GX400 |

| kapasitas | 42m3/h |

| daya motor | 11 kW |

16. produksi meneng conveyor 3 sawise elevator

| jinis | GX400 |

| kapasitas | 42m3/h |

| daya motor | 11 kW |

17. Mesin akeh

| kapasitas | 100t/jam |

| jarak fleksibel saka discharging gate | 1200 mm |

| daya motor | 0,55 kW |

| daya penggemar Filter | 2,2 kW |

18. Lift hoist produksi

| TB60 | TB60 |

| kacepetan hoist | 1.1m/s |

| kapasitas | 60m3/jam |

| daya motor | 15 kW |

18. Saringan

| jinis Filter buliding utama | HMC48 |

| daya | 4Kw |

| jinis packing filter | HMC48 |

| daya | 4Kw |

19. daya kompresor udara: 37Kw

20. sistem kelistrikan

Sistem iki didhukung dening ac 380V lan 50Hz telung fase papat (lima) sistem kabel.

21. kontrol komputer

otomatis lan manual

22. wektu siklus

| otomatis | 240s |

Katrangan

SjGJD060-3G stepped-jinis mortir batching peralatan adopts stepped-jinis struktur, kang nduweni karakteristik produktivitas gedhe, stabilitas lan linuwih, lan bisa digunakake kanggo nyawiji mortir garing biasa lan khusus garing mortir.The ndhukung mesin inang adopts SJGD4500-5B siji horisontal poros bajak-jinis mixer, kang nduweni ciri saka efficiency nyawiji dhuwur lan uniformity nyawiji dhuwur, lan rasio nyawiji bisa tekan 1:10000.

Konfigurasi

| peralatan standar | ||||

| Ora. | Katrangan | Item | Qty | Tetembungane |

| 1 | Piranti kerekan pasir garing | 1 |

| |

| (33m, 15 KW) lift | 1 | |||

| platform lan andha | 1 | |||

| chute saka dipakani lan discharging | 1 | |||

| 2 | layar gradasi | 1 |

| |

| 3. lapisan jaring layar: ngisor: 0.65mmmid: 1.2mm, ndhuwur 2.4mm | 2 | |||

| chute saka dipakani lan discharging | 1 | |||

| 3 | 砂仓除尘及出料sand silo | 1 |

| |

| ngeculake chute | 4 | |||

| (DN300) katup | 4 | |||

| katup pneumatik | 4 | |||

| Filter HMC48 Kab | 1 | |||

| 4 | timbangan semen lan pasir | 1 |

| |

| 3000kg timbangan pasir max 3000kg | 1 | |||

| sensor tekanan | 3 | |||

| (DN250) katup pneumatik | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 1500kg | 1 | |||

| sensor tekanan | 3 | |||

| katup pneumatik (DN250) | 1 | |||

| vibrator MVE60/3 | 1 | |||

| 5 | sistem pangiriman campuran | 1 |

| |

| meneng GX500 | 1 | |||

| aksesoris | 1 | |||

| 6 | elevator hoist campuran | 1 |

| |

| Lift TB110 (约20m, 22kw) | 1 | |||

| chute saka dipakani lan discharging gate | 1 | |||

| 7 | pakan aditif lan tank panyimpenan | 1 |

| |

| silo aditif (V: 2m3) | 4 | |||

| rotary level meter | 4 | |||

| katup manual (DN300) | 4 | |||

| katup pneumatik (DN150) | 4 | |||

| vibrator MVE60/3 | 4 | |||

| sistem saringan | 1 | |||

| 8 | skala ukur aditif | 1 |

| |

| regane maksimal 150kg | 1 | |||

| sensor tekanan | 3 | |||

| katup pneumatik (DN250) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 9 | piranti hoist aditif | 1 |

| |

| nyokong | 1 | |||

| rel | 1 | |||

| kandang kerekan | 1 | |||

| hoist listrik 2000kg | 1 | |||

| 10 | piranti dipakani manual | 1 |

| |

| silo pakan manual | 1 | |||

| katup pneumatik (DN200) | 1 | |||

| 11 | hopper panyimpenan tengah | 1 |

| |

| awak hopper | 1 | |||

| sensor tekanan | 1 | |||

| katup pneumatik (DN300) | 2 | |||

| vibrator MVE60/3 | 1 | |||

| 12 | sistem pencampuran (V: 4500L) | 1 |

| |

| piranti nyopir 90KW | 1 | |||

| piranti nyampur | 1 | |||

| kacepetan dhuwur Rotary scraper 5.5KW | 4 | |||

| gapura ngeculake | 1 | |||

| tank campuran | 1 | |||

| piranti sampel | 1 | |||

| 13 | hopper panyimpenan | 1 |

| |

| awak hopper | 1 | |||

| vibrator MVE 60/3 | 2 | |||

| feeder impelled | 1 | |||

| rotary level meter | 1 | |||

| katup pneumatik 4 fase | 1 | |||

| 14 | mesin akeh lan packing | 1 |

| |

| mesin akeh | 1 | |||

| awak hopper | 1 | |||

| rotary level meter | 2 | |||

| vibrator MVE 60/3 | 2 | |||

| mesin packing pindho metu | 1 | |||

| mesin sabuk (L=2500m,B=650mm,2.2kw) | 1 | |||

|

| ||||

| 15 | hoist produksi lan sistem pangiriman | 1 |

| |

| elevator (19m, 15kw) | 1 | |||

| andha lan platform | 1 | |||

| chute saka dipakani lan discharging gate | 1 | |||

| distributor rotary | 1 | |||

| 16 | produksi massal | 1 |

| |

| chute saka discharge | 4 | |||

| katup insert pneumatik | 4 | |||

| katup pneumatik (DN300) | 4 | |||

| hopper transisi | 1 | |||

| mesin akeh | 2 | |||

| 17 | piranti Filter bangunan utama | 1 |

| |

| Pulse back flush filter 36m2 4KW | 1 | |||

| pipa saringan | 1 | |||

| katup manual (DN150) | 2 | |||

| katup pneumatik (DN250) | 1 | |||

| 18 | packing piranti Filter | 1 |

| |

| Pulse back flush filter 36m2 4KW | 1 | |||

| katup manual (DN150) | 1 | |||

| pipa saringan | 1 | |||

| 19 | sistem pneumatik | 1 |

| |

| kompresor hawa | 1 | |||

| tank panyimpenan 1m3 | 1 | |||

| tank panyimpenan 0,3m3 | 2 | |||

| saringan utama | 1 | |||

| pengering | 1 | |||

| sendi | 1 | |||

| 20 | sistem kontrol | 1 |

| |

| komputer industri | 1 | |||

| piranti lunak | 1 | |||

| komponen listrik | 1 | |||

| inverter frekuensi utama | 1 | |||

| monitor LED | 1 | |||

| printer | 1 | |||

| sumber daya | 1 | |||

| meja operasi | 1 | |||

| carbinet listrik | 1 | |||

| kabel lan kabel | 1 | |||

| 21 | sistem pengawasan | 1 |

| |

| kamera warna | 4 | |||

| "lensa amera kab | 4 | |||

| 19 Monitor LED | 1 | |||

| masang DV | 1 | |||

| 22 | kamar kontrol | 1 |

| |

| pigura kamar kontrol | 1 | |||

| dekorasi njero lan njaba | 1 | |||

| katerangan lan ngalih | 1 | |||

| AC | 1 | |||

| 23 | Struktur baja utama | 1 |

| |

| sasis | 1 | |||

| andha | 1 | |||

| sikil ndhukung | 1 | |||

| Peralatan pangiriman panyimpenan | ||||

|

|

| |||

| 24 | semen screw conveyor | φ219-2140 | 4 |

|

| 25 | 机additive screw conveyor | Ø114-2000 | 2 |

|

| 26 | 机additive screw conveyor | Ø114-1300 | 2 |

|

| 27 | produksi screw conveyor (sadurunge elevator) | GX400-6500 | 1 |

|

| 28 | produksi screw conveyor (sawise mesin akeh lan elevator) | GX400-5000 | 2 |

|

| 29 | tong sampah bahan baku (现场制作) | 1 |

| |

| sand silo: diameteripun 3.4m, V 90m3 | 4 | |||

| Silo semen: diameteripun 3.4m, V 90m3 | 4 | |||

| katup manual | 4 | |||

| level meter | 8 | |||

| pemecah lengkungan | 4 | |||

| katup manual | 4 | |||

| level meter | 8 | |||

| katup aman | 4 | |||

| saringan pulsa bali | 4 | |||

| dukungan struktur baja | 1 | |||

| 30 | silo panyimpenan produksi |

| ||

| silo: diameteripun 3.4m, V: 75m3 | 4 | |||

| pemecah lengkungan | 4 | |||

| katup manual (DN300) | 4 | |||

| rotary level meter | 8 | |||

| (1.5kw) saringan flush bali pulsa | 1 | |||

| dukungan struktur baja | 1 | |||

| 31 | dekorasi | 1 |

| |

| dekorasi 2500m2(0.5mm) | 1 | |||

| pigura awak, jendhela lan lawang | 1 | |||